How to improve the welding quality of handheld laser welding machine? There are 8 steps improvement such as laser power adjustment, welding speed, focal length checking, welding gun inclination angle, wobble frequency & wobble width, filler wire selection, operator training, daily checking of protective lens. Improve the welding quality will extend the service life of laser welding machine at the same time

1. Power adjustment: During the welding process, set a suitable laser power to obtain the best welding effect. According to different materials and thicknesses, choose the appropriate power. Too much high laser power may cause melting too fast and cause dents or undercuts, or too low power will lead to unsuccessful welding. For example, the aluminum oxide on the surface of aluminum alloy has a higher melting point and high reflectivity. If the laser power is too low, most of the laser will be reflected away. Therefore, it is recommended that the welding power be above 1200w when performing ordinary welding of aluminum alloy. For example, copper alloy welding, because it is a highly reflective material, it is recommended that the laser power be greater than 2000w during wire welding.

2. Speed adjustment: During the welding process, the welding speed and the welding power should be coordinated with each other. When the material thickness is thin such as 1-2mm, the welding speed can be faster when the power is higher. When welding thicker materials or wire feeding welding, the welding move speed will be slower. If there are dents or undercuts in the welding, the welding move speed can be relatively increased.

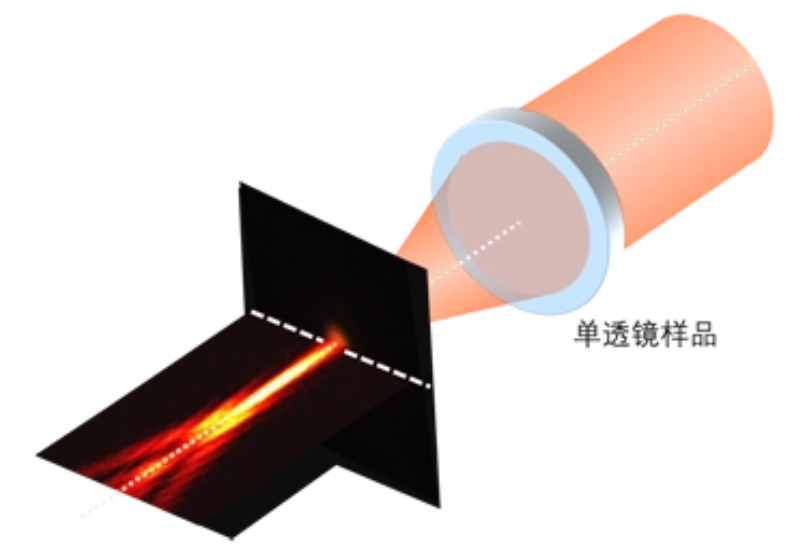

3. Adjustment of focus position: In handheld laser welding, adjustment of focus position (focal length) is crucial to welding quality. Find the correct laser focus position for optimal penetration depth and width. The correct focal length can ensure that the laser energy is more concentrated and improve the processing speed and efficiency. The correct laser focus is like cutting with the sharpest knife, the opposite is like a dull knife. For example, if adopts Raytools welding gun with a 20mm & F150 welding focusing lens, the generally measured correct focal length is as follows

.

4. Control of welding gun inclination angle: In handheld laser welding, the operator needs to master the correct welding angle and welding route to ensure that the shape of the weld meets the requirements and improve the strength and stability of the weld. There are two angles that need to be noted here. The first angle is that the welding gun is kept at about 75 degrees from the moving route (that is, the vertical direction of the welding gun and the moving route is kept at about 15 degrees). The second angle is that the welding gun is kept at same angles from the two pieces to be welded. The materials should generally maintain the same inclination angle. For example in Tee-joint welding, the recommended angle between the inclination angle of the welding gun and the two pieces of material is 45 degrees.

5. Selection of wobble frequency and wobble width: Generally the greater the wobble frequency of the welding gun, the smoother the weld will be, but the welding strength or penetration will decrease accordingly. The laser torch wobble width will also affect the strength of the welding. When welding thicker materials, the generally set wobble width should also be increased accordingly. Therefore, the wobble frequency and wobble width should be optimized according to the material thickness, weld surface requirements, strength requirements, etc.

6. Selection of filler materials: In handheld laser welding machine, the selection of filler materials (feeding wire) also has a great impact on the welding quality. Operators need to select appropriate filling materials based on different materials and thicknesses to improve the strength and stability of the welded joints. For example, S304 roll welding wire can be used for welding stainless steel materials, S201 copper roll welding wire can be used for copper or brass, and ER5356 roll welding wire can be used for welding aluminum alloys. As for the diameter of the welding wire, it is generally determined by the thickness of the welding material. For example, for material thicknesses of 1-3mm, you can use welding wires with diameters of 0.8, 1.0mm, and 1.2mm. For materials above 3mm, you can use welding wires with larger diameters, such as 1.2mm, 1.6mm, 2.0mm, or even adopts a dual wire automatic feeder

7. Training of operating skills: To improve the welding quality of handheld laser welder, it is also necessary to strengthen the training of operating skills. Operators need to master correct operating skills and methods, including welding posture, welding gun angle, welding speed, etc. Through training and practice, the skill level of operators can be improved, thereby improving the quality of welding.

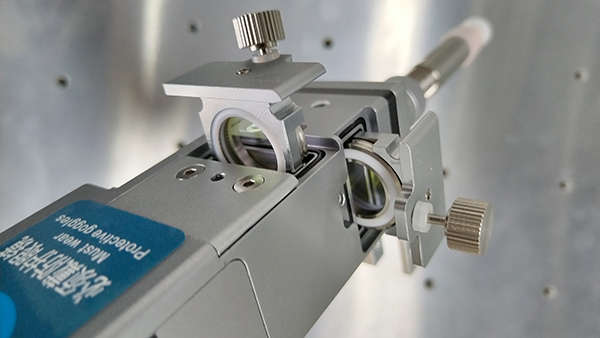

8. Daily inspection of welding gun protective lenses: As a consumable for handheld laser welding machines, daily inspection and replacement of protective lenses are very important. Usually the inspection and replacement of protective lenses every 1-7 days and depends on the frequency of using the welding machine and the level of power used. If laser welding is continued for a long time after the protective lens is damaged, not only will the focused laser power be greatly reduced, causing the originally set power to be unable to perform effective welding, but it may even cause other lenses & mirrors inside the laser welding gun damaged, such as the focusing lens, galvanometer mirrors, reflective mirrors & collimating lens.

By doing the above 8 items, I believe that you will have an easier understanding and grasp of handheld laser welding opportunities, which can greatly improve the efficiency of the laser welding machine, improve the strength and beauty of the weldseam, reduce the failure rate, and significantly extend the service life of laser welding machine

info@fivelaser.com

info@fivelaser.com