-

Pulsed laser cleaning machine: Very suitable for painting removal (coating removal), mold cleaning

The surface aluminum after laser cleaning, the left side one is cleaned by pulsed fiber laser, we can see paint on the surface has been completely removed, and there is little damaged and no laser lines; The right side one is done by continuous fiber laser, the paint was also completely removed, but there was a serious remelting phenomenon on the surface, and laser lines appeared

Comparison

The left side one is made by pulsed laser, the surface is relatively smooth; The right side one is made by continuous fiber laser, the paint was also completely removed, but the surface was remelted seriously, and the surface was uneven.

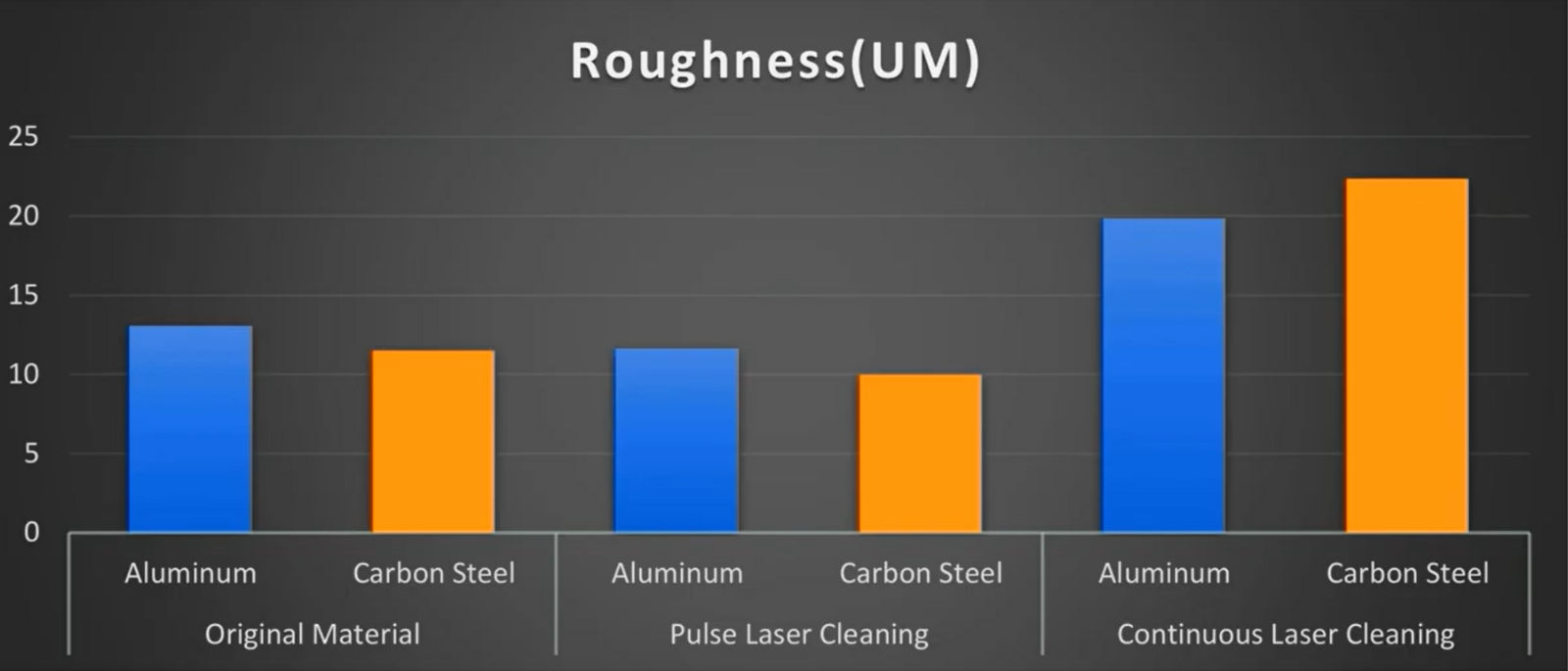

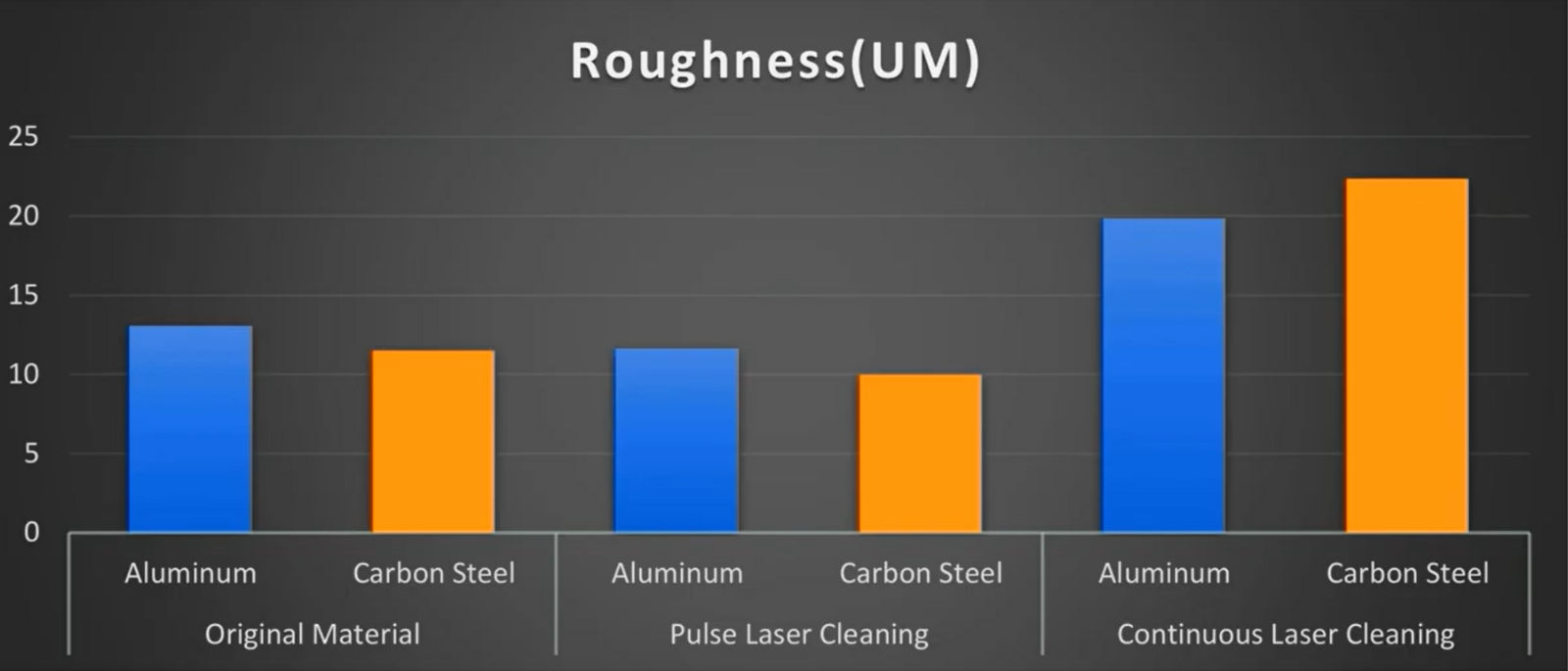

The pulsed laser damages the surface less, which the surface roughness after cleaning is close to that of the original materials. But after continuous laser cleaning, the damage to the surface is greater, so the surface roughness is 1.5 times the roughness of the original material and 1.7 times the surface roughness after pulsed laser cleaning

Comparison

The continuous laser cleaner will bring higher much temperature on based material surface during cleaning compare to pulsed laser cleaning machine. Pulsed lasers can better control the thermal input to prevent excessive substrate temperature or micro-melting, so that the pulse laser cleaning will lead to less damage or less distortion to the base metal plates compared with continuous laser cleaning

Pulse laser working on furniture coating removal. If need to do re-painting on furniture for renovation, then pulsed laser cleaner will be good choice

Both pulsed laser & continuous laser can do rust removal, but the continuous laser have advantage in rust removal. Also continuous laser cleaner has advantages in price, will pay less money in purchase continuous laser cleaning machine compare to pulsed laser cleaner

info@fivelaser.com

info@fivelaser.com